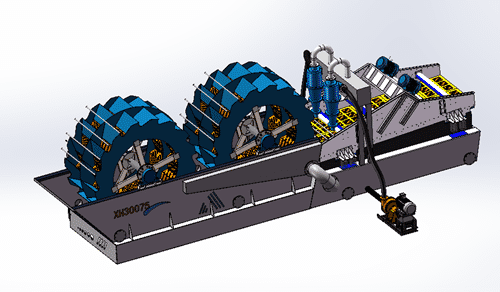

The double wheel sand washer is a new type of sand washing machine. On the basis of our original sand washing equipment, the equipment has been updated and upgraded to meet the needs of customers. The double wheel sand washing machine is skillful in docking two wheel bucket washing machines with fine sand recovery machines. The whole machine has a reasonable structure and small area, which greatly reduces the investment cost for customers in the sand washing link. It integrates heavy water washing and fine sand dehydration and recycling.

LZZG series introduced products to absorb foreign advanced technology, and designed combined with sand field actual situation. It can effectively reduce the loss amounts of fine material; solve problems of end product such as relatively high fineness modulus and relatively low stone powder content. The fine material can be recycled as high as 95%, with incomparable technical and economic advantages.

| Model | Feed Size(mm) | Capacity (t/h) | Impeller Size (mm) | Hydrocyclone (mm) | Screen Panel (mm) | Power (kw) | Overall Size (mm) |

| 2DL40 | ≤10 | 20-40 | 1800X800 | 250X2 | 1200X2400 | 32.4 | 7120X3650X2160 |

| 2DL60 | ≤10 | 30-60 | 2500X1200 | 300X2 | 1500X3000 | 44 | 8900X5560X2750 |

| 2DL80 | ≤10 | 40-80 | 3000X1600 | 300X2 | 1800X4200 | 52 | 11600X5860X3370 |

| 2DL100 | ≤10 | 60-120 | 3000X1600 | 350X2 | 1800X4200 | 63 | 11600X5860X3370 |

| 2DL150 | ≤10 | 100-150 | 3600X2000 | 300X4 | 2400X4200 | 97 | 12800X6560X3970 |

| 2DL200 | ≤10 | 120-200 | 3600X2400 | 350X4 | 3000X4800 | 126 | 12800X7150X4170 |

| 2DL250 | ≤10 | 160-250 | 4200X3000 | 300X6 | 3600X6000 | 164 | 14400X7740X4860 |

The dual wheel sand washing machine integrates two set wheel sand washing machines with the dewatering screen and hydrocyclone separator, which is specially designed for washing, grading, recycling, and concentrated dewatering of coarse and fine materials. Dual wheel sand washing machines can widely process sandstone and quartz sand, aggregate, coal, ore, tailing, etc. The sand can be cleaned, dehydrated and graded twice, which will greatly reduce the content of mud and impurities and water in sand and improve the sand quality. Dual wheel washing machine is is upgraded and developed based on the original sand washing and recycling equipment.

The dual wheel sand washing machine integrates two set wheel sand washing machines with the dewatering screen and hydrocyclone separator, which is specially designed for washing, grading, recycling, and concentrated dewatering of coarse and fine materials. Dual wheel sand washing machines can widely process sandstone and quartz sand, aggregate, coal, ore, tailing, etc. The sand can be cleaned, dehydrated and graded twice, which will greatly reduce the content of mud and impurities and water in sand and improve the sand quality. Dual wheel washing machine is is upgraded and developed based on the original sand washing and recycling equipment.

Working principle

Working principle

The material after pre-treatment enters first cleaning tank, under the constant rotation and stirring of impeller, material is full mixed into water, and the impurities on the surface of material are taken away by water to make material cleaner. Then the impeller picks up material from the water and leaks water and impurities, and transfers the qualified material to the second tank and repeat the process in first tank, so the materials is further cleaned twice. Then enter to dewatering screen, and remove a large amount of water through the vibration of dewatering sieve, so that the material is more convenient to store and transport. The material leaked in water tank enters slurry pump through overflow device, and is pumped to the hydrocyclone for concentration and recovery. After concentration, the qualified materials are returned to dewatering screen for dehydration. The excess muddy water and impurities enter the return tank.

Features

1. Multiple functions, integrate sand washing, fines recycling, coarse and fines concentrated dehydration in one.

2. By connecting the two sand washers in series and the spray water pipes arranged around them, the material can be cleaner fully.

3. The fines recovery device can recover more than 90% of fines in the overflowing muddy water during sand washing, to make the finished sand grading well, and effectively improve the economic benefits.

4. If the muddy water treatment system is configured later, the pressure of concentrated filter press can be greatly reduced, so that the entire process can be optimized.

5 common faults of sand washing machinesThe sand washing machine is indispensable production equipment in the mechanism …

What are the factors of sand-making machine vibrationThe rotor is the core component of the impact sand-making machine. After the rot…

Identify and improve the quality of machine-made sandAs for the machine-made sand on the market, the price and quality of the machine…

Affects the price of equipment of fine sand recycling machineThe fine sand recovery equipment is one of the essential pieces of equipment on …

We pride ourselves in our commitment and the level of service offered and aim to work closely with customers, to ensure we meet your expectations. Our objective is to keep your business operations running as smoothly as possible on a day-to-day basis.

If you need the latest price list, please leave us a message here! We guarantee that your information will not be divulged to the third parties, and we will reply to you within one working day, thank you.

We are here for your questions anytime 24/7, welcome your consultation.

The latest sand washer price.

Installation and maintenance.

Screening

Sand Washing Machines

Sludge Treatment

Sand Recycling Machines

Address: Shuangyue Road, Changdai Town, Mengjin County, Luoyang, China

Email: export@lylzzg.com

Tel: +86-379-65160016