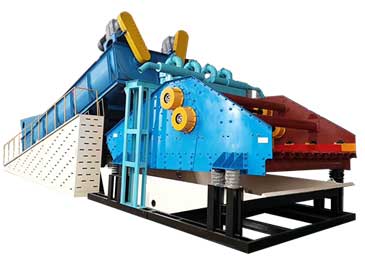

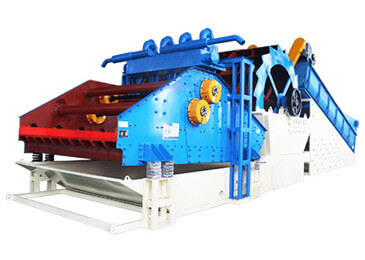

The sand washing machine is sand washing equipment (artificial sand, natural sand), which can be widely used in the washing process of stone materials in industries such as sand and gravel plants, building materials, chemicals, highways, railways, water conservancy, and hydropower. It can remove the covering The impurities on the surface of the sand and stone will destroy the water vapor layer that wraps the sand grains and achieve dehydration, thus playing the role of efficient sand cleaning.

During the use of the sand washing machine, there will be some problems such as unclean sand washing and reduced sand washing volume. This article introduces some problems and solutions during the use of the sand washer.

When washing sand, you should first let go of the flushing pipe, and then feed the sand for washing. The amount of water delivered should be moderate to keep the cleaning and clean and prevent the sand from overflowing along with the slot. When feeding, it must be uniform, and not too much or too quickly. These will affect the quality of the sand.

1. The sand net is damaged.

2. The fixing bolts of the sand net fall off.

1. Check and repair or replace the sand net.

2. Tighten the bolts.

1. The grease is dirty.

2. Improper amount of grease.

3. The bearing is damaged.

1. Replace the grease.

2. The amount of grease must be moderate, not too much or too little.

3. Replace the bearing.

This is the most likely problem in the operation of the sand washer. Most of the reasons are due to the too fine grain size of the sand in the slurry of the sand washer, and the single feeding amount suddenly increases, resulting in material deposits at the discharge port.

Feeding should be stopped first. Then open all the discharge ports to avoid siltation. Finally, clean the sand washer with clean water before proceeding.

1. The bearing is damaged.

2. The reducer is faulty.

3. The bucket body rubs the shell.

1. Replace the bearing.

2. Overhaul the reducer.

3. Overhaul and adjust the wheel bucket body.

1. No timely maintenance.

2. The shaft of the sand washer and the low-speed shaft of the reducer does not reach the required parallelism.

1. Refuel at the specified time.

2. Adjust the gear to meet the requirements.

1. The oil is cut off or the sealing ring is damaged.

2. Long-term lack of maintenance and cleaning.

1. Refuel or replace the sealing ring as required.

2. Regular inspection and cleaning.

Regular maintenance and maintenance can also reduce the failure rate of the sand washing machine, and can ensure the operation of the equipment and extend the service life of the equipment.

Please enter your inquiry and contact. We will reply you as soon as possible.

We are here for your questions anytime 24/7, welcome your consultation.

The latest sand washer price.

Installation and maintenance.

Screening

Sand Washing Machines

Sludge Treatment

Sand Recycling Machines

Address: Shuangyue Road, Changdai Town, Mengjin County, Luoyang, China

Email: export@lylzzg.com

Tel: +86-379-65160016