The dust removal efficiency of the cyclone dust collector is related to the particle size of the dust particles. The larger the particle size, the higher the efficiency. When the particle size reaches a certain value, the dust removal efficiency of the cyclone dust collector can reach 100%. So how to improve the efficiency of the cyclone separator?

Increasing the flow rate of the intake pipe within a certain range can improve the efficiency of dust removal. However, if the inlet flow rate is too high, some of the separated dust particles will be drawn into the inner swirling flow and taken away again, resulting in a drop in dust removal efficiency. In addition, the pressure loss is proportional to the square of the inlet velocity. If the inlet flow velocity is too large, the pressure loss will increase. thus. From the comprehensive consideration of technology and experience, the appropriate range of inlet flow rate is generally 12-20m/s, and should not be less than 10m/s to prevent dust accumulation in the inlet pipe.

The smaller the simplified diameter, the greater the centrifugal force on the dust particles and the higher the size efficiency under the same tangential speed. The change of the simplified height has no obvious effect on the dust removal efficiency, and the proper lengthening of the height of the cone is beneficial to improve the dust removal efficiency.

Since the centrifugal force of dust particles is proportional to the third power of the particle size, and the radial air resistance received is only proportional to the first power of the particle size, the large particle size is easier to trap than the small particle size. The dust removal efficiency increases with the increase of the true density of the dust particles. The density is small and difficult to separate, and the dust removal efficiency decreases.

The gas viscosity increases with the increase of temperature, and the divided particle size is proportional to the square root of the viscosity, so the dust removal efficiency of the cyclone dust collector decreases with the increase of gas temperature and viscosity.

The internal static pressure of the dust collector gradually decreases from the outer wall to the center. Even if the dust removal is operated under positive pressure, the bottom of the cone may be under negative pressure. If the lower part of the dust collector is not tight and the air leaks, the dust that has fallen into the ash hopper will be taken away again, and the dust removal efficiency will be significantly reduced.

If the above five aspects can be well controlled, then the efficiency of the cyclone separator can be improved. If you have other questions about using the cyclone separator, you can contact us at any time.

Please enter your inquiry and contact. We will reply you as soon as possible.

We are here for your questions anytime 24/7, welcome your consultation.

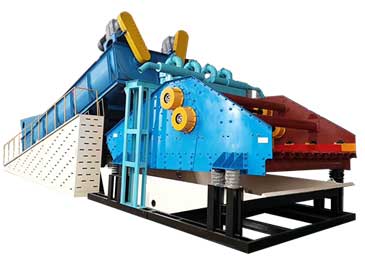

The latest sand washer price.

Installation and maintenance.

Screening

Sand Washing Machines

Sludge Treatment

Sand Recycling Machines

Address: Shuangyue Road, Changdai Town, Mengjin County, Luoyang, China

Email: export@lylzzg.com

Tel: +86-379-65160016