In the sand production line of Sri Lank, when different sand washing machines clean sand and gravel, the phenomenon of fine sand loss will occur. These lost fine sands cause the loss of each production line may reach 6%-30%. If the lost part of the fine sand is recovered, then this part of the profit is also considerable.

The sand washer is divided into wheel sand washer and spiral sand washer. The bucket sand washer is widely used for material washing in mining, building materials, chemical industry, transportation, concrete mixing plant, and other fields. The spiral sand washing machine uses the propelling action of the propeller to clean the sand. Compared with the wheel sand washing machine, the spiral sand washing machine has higher cleanliness.

However, no matter what kind of sand washing machine, most of the sand and gravel will inevitably be picked up during the mixing process, and the gravel will flow away along with the sink, which will cause the phenomenon of sand and gravel loss. The following article shares three fine sand recovery methods to solve the problem of serious fine sand loss.

The sand washing wastewater flows into the sedimentation tank. After a period of time, the sediment will be deposited layer by layer. Due to the heavier weight of sand and soil, they can be separated after a long time. Of course, this method also has its shortcomings, long-term precipitation process Occupies a large area of sedimentation tanks, resulting in manual excavation of sedimentation sand and sedimentation mud, which consumes more time and labor.

The sand washing waste-water is directly discharged to the screen surface of the linear dewatering screen to recover the lost sand. The disadvantage is that if there is no mud in the raw material, then there is no problem, but if there is too much mud, it will not play the role of sand recovery, so before using this device, you must carefully refer to the instructions.

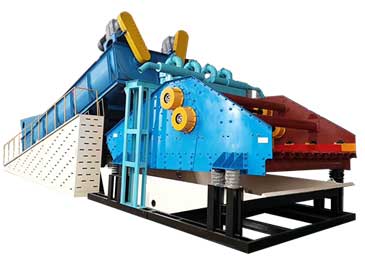

The sand washing wastewater is directly discharged to the lower water tank part of the fine sand recovery machine. The mud pump is used to drive the mixed sand and mud water to the rotary separator, and then discharge to the surface of the screen. The fine sand part is discharged together with the mud and water. It flows back to the lower water tank again to form a cycle to continuously extract sand from the waste-water. This method effectively improves the efficiency of fine sand recovery and increases the output of sand.

Through the above three methods, we found that the sand washing machine equipped with a fine sand recovery machine for sand recovery is the best choice. Thank you all, if you want to know more, please follow us!

Please enter your inquiry and contact. We will reply you as soon as possible.

We are here for your questions anytime 24/7, welcome your consultation.

The latest sand washer price.

Installation and maintenance.

Screening

Sand Washing Machines

Sludge Treatment

Sand Recycling Machines

Address: Shuangyue Road, Changdai Town, Mengjin County, Luoyang, China

Email: export@lylzzg.com

Tel: +86-379-65160016