The sludge treatment equipment is one of the indispensable building materials at present. Especially during the peak period of urban construction, the demand for sludge treatment equipment is also increasing year by year. The role of the sludge treatment equipment in construction is becoming more and more prominent, but the production and transportation of sludge treatment equipment will inevitably produce a large amount of sewage.

The sewage sludge treatment equipment of the concrete mixing plant designed and developed by lZZG plays an essential role. The main sources of this sewage produced by concrete mixing are sewage produced by cleaning transport vehicles, sewage produced by site cleaning, and sewage produced by cleaning of supporting facilities of mixing building during production. The sewage contains not only cement, soil, sand, and other materials, but also oil stains, concrete additives, and other ingredients. If the sewage is not effectively treated and used, and allowed to be discharged naturally, it will cause serious pollution to the environment

The sewage treatment system of the mixing station designed by lZZG mainly includes sewage treatment pipelines, oil separation sedimentation tanks, thick sewage tanks, sludge separation equipment, sewage pumps, filter presses, and automatic control systems. The wastewater produced during the production process of the concrete mixing plant not only contains conventional construction materials such as sand and cement but also contains concrete additives. If it is directly discharged, it will cause serious pollution to the natural environment. The sewage treatment plant of concrete mixing plant designed and developed by lZZG is a closed automatic sewage treatment system. In accordance with the principle of recycling, the wastewater is separated from mud and sand, separated from mud and water, and solid waste is discharged dry. Make the entire concrete batching plant production plant realize the concept of environmentally friendly production.

The main equipment of the production line includes sewage treatment pipelines, sewage tanks, clean water tanks, sediment separation equipment, screening fine sand recovery equipment, thickening tanks, filter presses, and other parts.

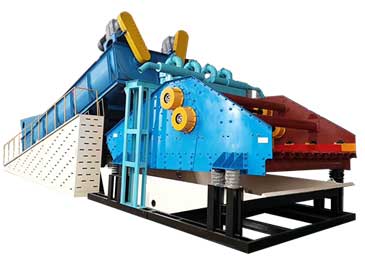

1. Sediment separation equipment

A dewatering screen can be used to dewater the sand and gravel, and the swinging screen can classify the sand and gravel for reuse of raw materials.

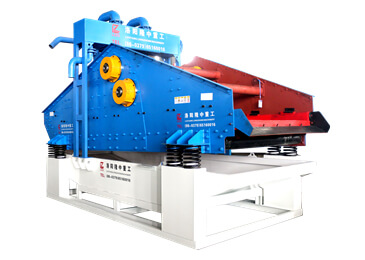

2. Fine sand recovery equipment

The sand washing and recycling integrated machine or the fine sand recycling machine can be used to realize the washing, dewatering, and recycling of the materials under the screen after screening through the cyclone.

3. Concentration tank

The separation of mud and water is achieved through concentration and sedimentation, and the purification of tailwater is realized.

4. Filter press

The thickened sludge in the thickening tank is pressed into a sludge cake through a belt filter press or a box filter press to achieve sludge dewatering and dry stacking.

The sewage sludge treatment equipment of the lZZG concrete mixing plant can effectively treat and recycle the sewage in the concrete production plant area to ensure zero discharge of sewage in the plant area and achieve the goal of clean production. The sewage treatment plant of the concrete mixing plant is highly pertinent, and the equipment can be configured according to the customer’s situation. For more equipment information, you can call lZZG. Professional solution engineers will design and recommend production lines and stand-alone equipment for you. Allows you to see real-life cases and stand-alone equipment video explanations without leaving home.

Please enter your inquiry and contact. We will reply you as soon as possible.

We are here for your questions anytime 24/7, welcome your consultation.

The latest sand washer price.

Installation and maintenance.

Screening

Sand Washing Machines

Sludge Treatment

Sand Recycling Machines

Address: Shuangyue Road, Changdai Town, Mengjin County, Luoyang, China

Email: export@lylzzg.com

Tel: +86-379-65160016