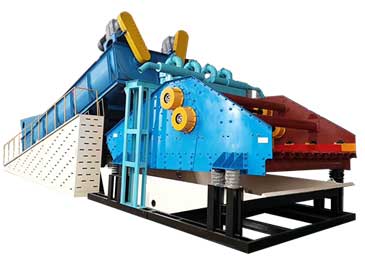

In the production of artificial sand, the sand washed by the sand washing machine is cleaner and has better quality. Therefore, the sand washing machine has gradually become an important piece of equipment in the artificial sand production line. The following author shares some installation requirements for the sand washing machine.

1. After the sand washing machine is delivered, the user should immediately check whether the parts are complete and whether they are damaged, and after confirming that the machine is intact, it can be installed.

2. The user should design the foundation construction drawing of the sand washer according to the specific conditions of the site, and install the sand washer firmly on a solid concrete foundation.

3. When installing the spiral sand washer, the inclination angle must be ensured according to the requirements of the installation drawing, and whether the motor installed in the sand washer is on the guide rail, and the tightness of the belt needs to be adjusted.

4.After the installation is complete, rotate the rotor disc to see if there are paper jams and collisions.

After starting the sand washer, a trial run must be carried out.

1. No-load operation and debugging of sand washing machine

After the motor is started, the sand washer should run smoothly without abnormal vibration. The bearing temperature rise must not exceed 35°C. The sand washer runs for 2-4 hours without any problems, check whether the connection is loose, and then make adjustments.

2. Load operation debugging of sand washing machine

The sand washing machine can carry out the load test only on the basis of a good no-load test operation. The sand washing machine should run smoothly without abnormal vibration. The bearing temperature rise should not exceed 40°C. No dust can enter each seal.

1. Excessive bearing wear and poor assembly. We must check the bearings of the sand washer in time. If the bearings are found to be severely worn, they should be replaced in time to prevent the motor from overheating.

2. The iron core of the sand washing machine is corroded. This may be due to humidity. Sandpaper can be used to polish the iron core, and then apply a layer of insulating paint on the surface to prevent rust again.

3. The joint between the iron core and the base is loose. Tighten the original positioning screws. If it is not easy to operate, please pre-punch holes on the base for positioning.

4. The journal of the sand washer is worn. Check the degree of wear of the journal, if the wear is not too serious, you can directly plate a chrome layer on the journal. If the wear is severe, cut off a layer of chromium, and then put it on the tube.

The above are the precautions for the installation and use of the sand washer. If there are any problems that you cannot solve during the use, you can contact us to help you solve them. LZZG Heavy Machinery is looking forward to your visit.

Please enter your inquiry and contact. We will reply you as soon as possible.

We are here for your questions anytime 24/7, welcome your consultation.

The latest sand washer price.

Installation and maintenance.

Screening

Sand Washing Machines

Sludge Treatment

Sand Recycling Machines

Address: Shuangyue Road, Changdai Town, Mengjin County, Luoyang, China

Email: export@lylzzg.com

Tel: +86-379-65160016